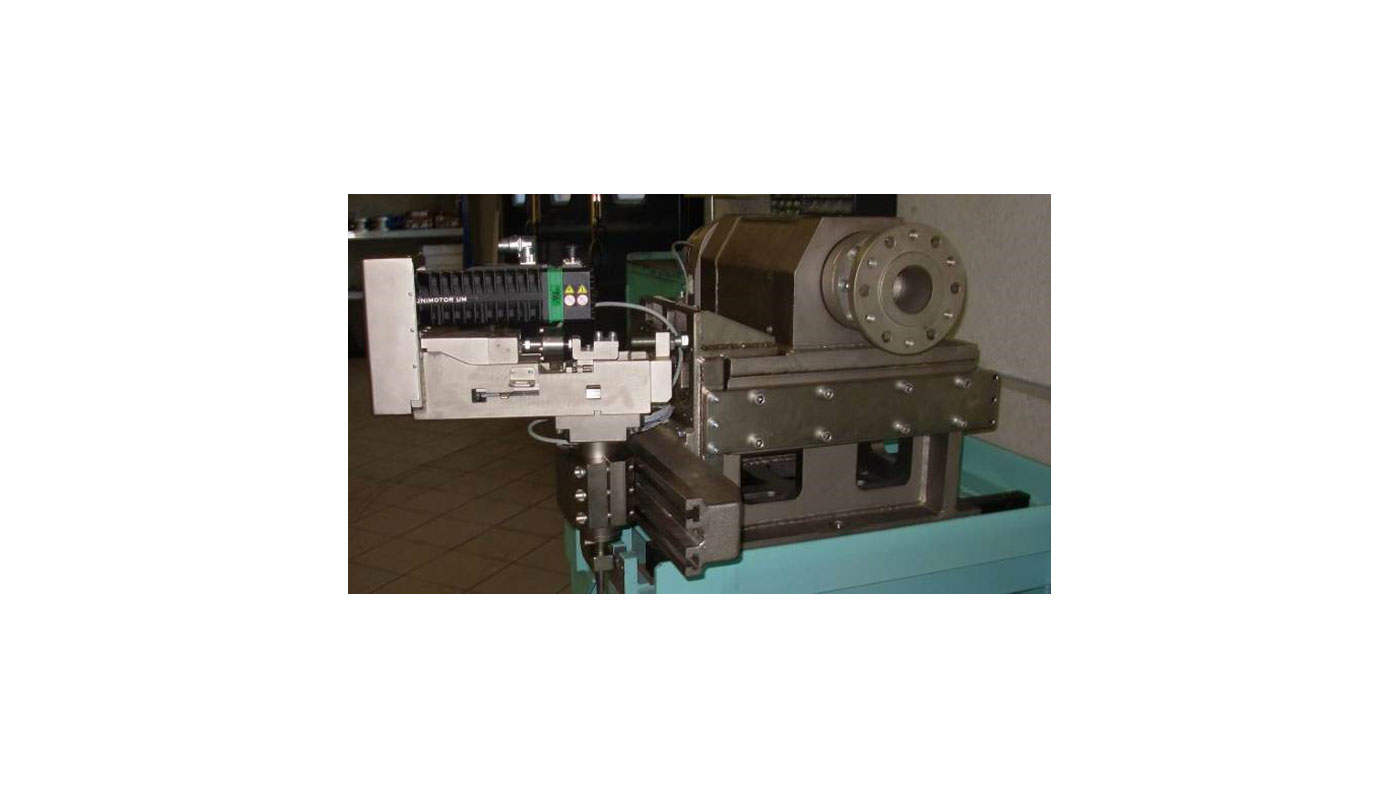

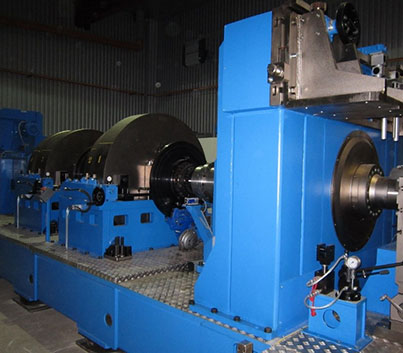

- Speed: 0-28 rpm

- Max. braking torque: 7000 Nm

- Motor 10.6 kW

- Max. pressure: 250 bar

- Handbrake actuator: max. strength 5000 N

- EPB Trolley (electric parking brake): integrated with handbrake pull

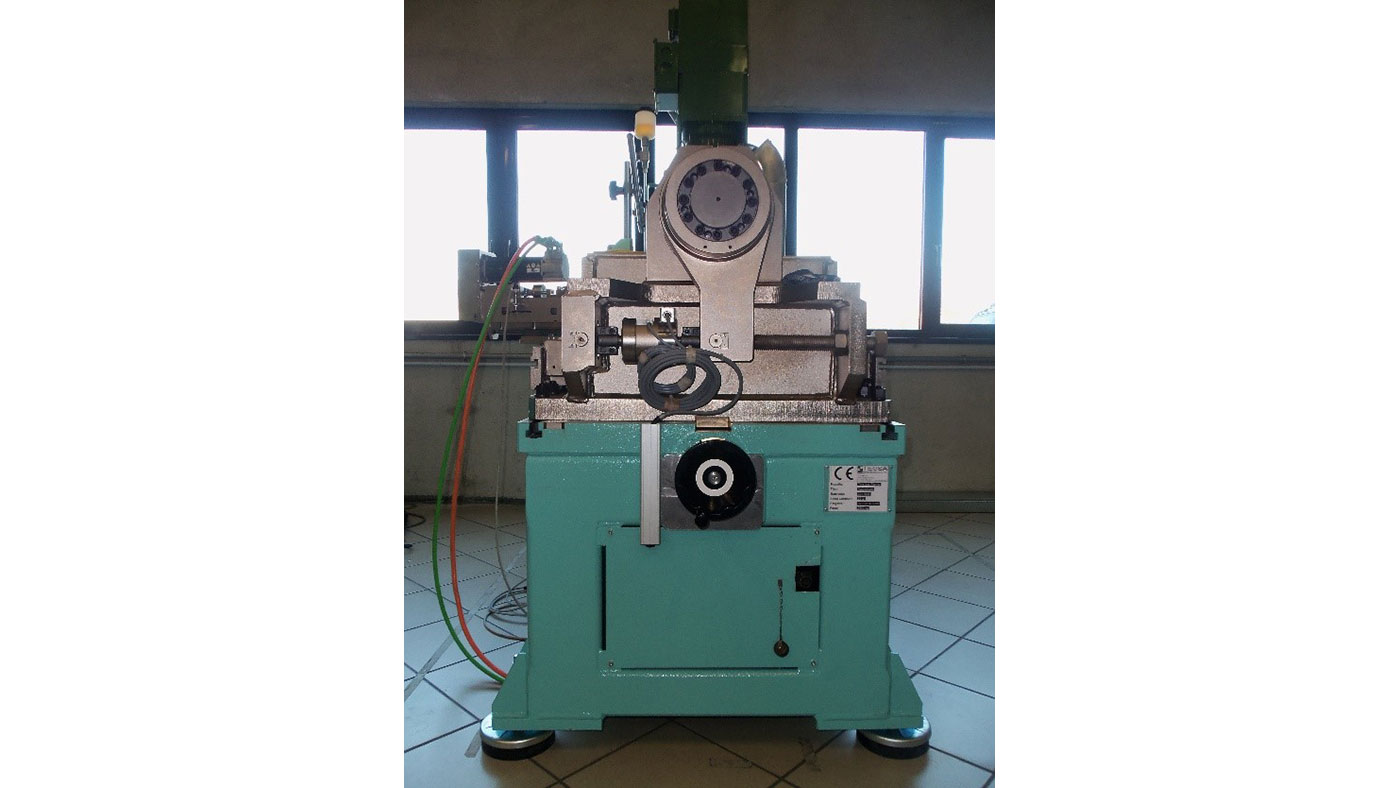

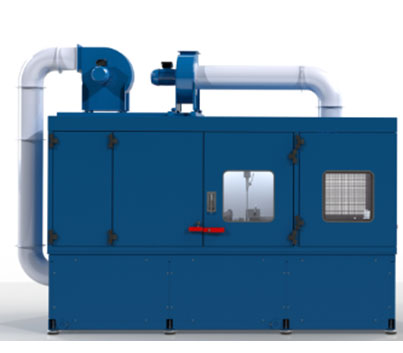

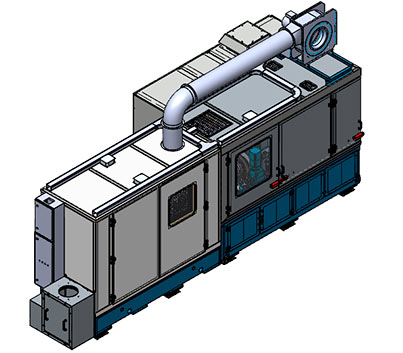

AT 7000

Fatigue tests on parking brakes

- Stress tests on braking systems (typically drum brakes)

- Alternate torsion tests

- Simulation of the solicitations of the brake systems on vehicle (e.g. car transporter)