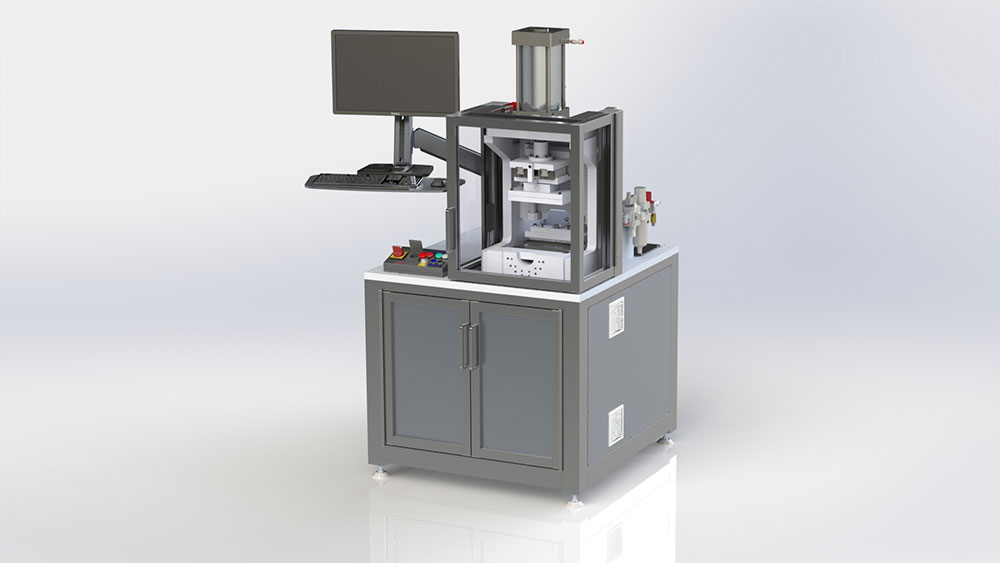

TecSA proposes SST machine, to test the shear strength of brake pads. This test is requested by several international regulations, such as the homologation of brake pads for After Market and the Conformity of Production test as foreseen in ECE-R90 ruling.

The SST can test brake pads whose maximum surface is 250 square centimeters and can test the shear strength of brake pads of whatever shape and height. The ram is the only tooling that is necessary to specifically manufacture for every pad. The ram shall match with the shape of the brake pad. The ram has a central fixing point, that is easily blocked with screws.

The housing area of brake pad is 300 mm x 125.

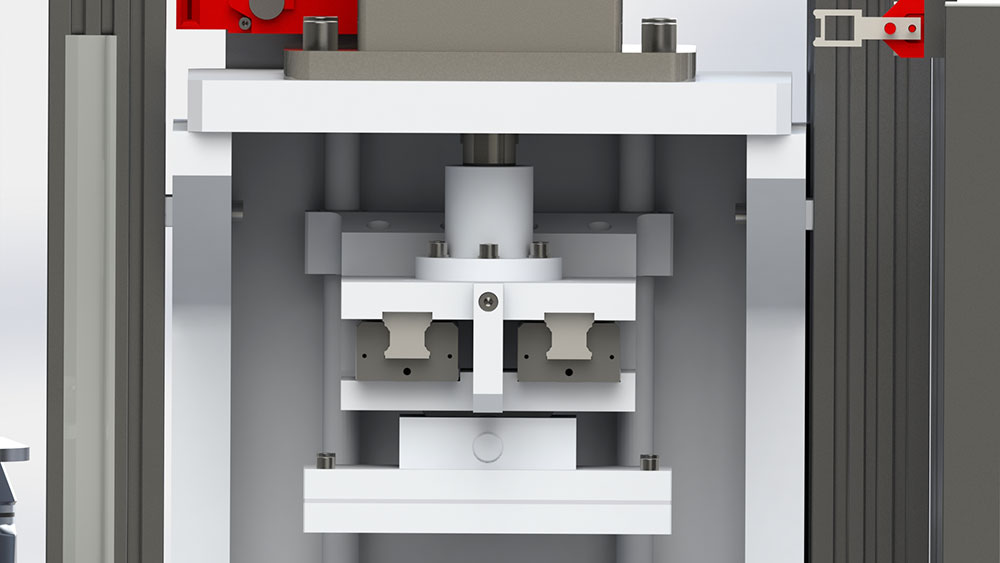

Brake pad housing

A simple grid is used to house and fix whatever pad, regardless of the number and the placement of the pins on its basement.

The lifting of the support plane regulates the height of the housing of the brake pad in relation to the ram. Height regulation is 4 mm and each turn is 2 tenths. Each notch corresponds to 2 hundredths.

The tilting vertical presser adapts to the surface of the pad and has a horizontal scrolling movement, that eliminates the interference of the friction of the pressure in relation to the movement of the ram.

The SST can test pre-heated pads, up to the temperature of 600° C, without any interference with the functioning of the machine. The SST self-centers the brake pad. Then, the user can regulate its placement.

The surface of the friction material can be irregular, to test worn brake pads. Through the vertical presser, it is possible to use whatever contrast material (such as another brake pad) and run the test.

Shear pad

The ram slowly moves and approaches to the pad. Then, the vertical presser goes down to provide the requested pressure. Once the pad is blocked, shear stress begins, up to reach the values pre-defined by the software. Once the shear is completed, shear diagram is displayed by the software.

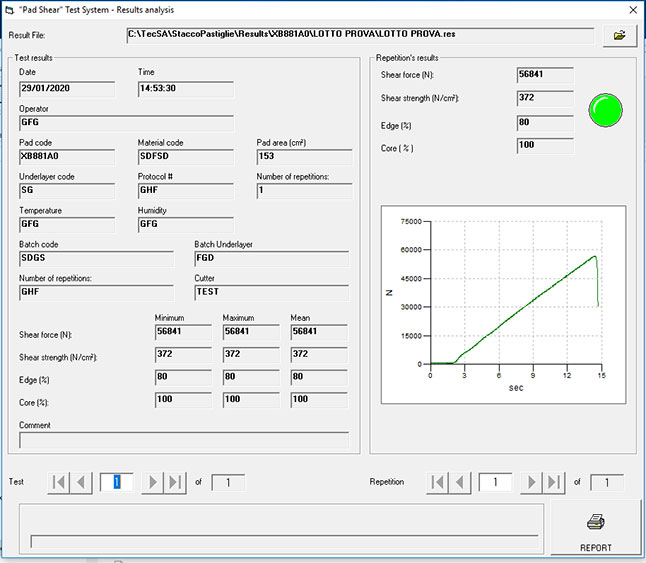

Then, the user analyzes the surface of the friction material that has been sheared from the lining and, finally, the user rates it in a percentage value. The software automatically elaborates the data of the test and drafts the report, in tabular and graphic formats. The report is finally filed and the test is concluded.

Software

TecSA software is highly user-friendly. It is possible to load the data already registered in the archive or, alternatively, to fill the forms. The first information to be filled is pad’s area. On this basis, the software can calculate the strength of the vertical presser. Additional data to be filled are the code of the pad, batch number, underlayer and back-underlayer codes, progressive batch of production, temperature and humidity. The user can choose between single shear and shear of several pads. In the latter case, the final result is the average outcome among several shears.

Calibration

TecSA offers to its Customers a service of periodical calibration. However, through a specific software module our Customers can autonomously calibrate TecSA machines without the assistance of our staff. Requested tools are a sample load cell and a monitor.

The user selects the calibration of the pressure of the ram or of the vertical pressure, then selects the strength to be obtained.The presser applies the requested strength on the load cell.The visualizer shows the measured strength.

Once measured strength has a fixed value, the user presses START acquisition and then STOP acquisition. The software elaborates the average acquired value. Requested value: 5000 N. Acquired value: 5010 N. Measured value: 5013 N. The machine is duly calibrated. Then, the user will acquire different values.

Once the calibration is concluded, the software elaborates calibration certificate, to be stamped and filed.